Nitrogen dioxide gas detector GE-NO2

The GE-NO2 gas detector is a meticulous innovation designed for industrial environments and locations prone to nitric dioxide (NO2) leaks; Equipped with a high-precision electrochemical sensor and fuel cell technology, the detector guarantees stability and consistency in NO2 detection; Its rugged IP66-protected housing houses a removable electrochemical cell and special electronics; It incorporates a capillary diffusion barrier and a stainless steel filter for protection against contamination; Although durable, the sensor should be replaced every two years under normal conditions; It offers reliability, corrosion resistance and exceptional stability even under extreme conditions;

The GE-NO2 gas detector has been meticulously designed for deployment in industrial environments and anywhere there may be the possibility of an abnormal leak or buildup of nitric dioxide (NO2) gas; Dada la naturaleza peligrosa del NO2 para tanto las personas como los objetos, contar con un dispositivo fiable como este es fundamental para garantizar la seguridad en estos entornos.

This detector uses a precision electrochemical cell sensor as its main sensitive component; This type of sensor has several significant advantages, such as its stability and the ability to provide consistently repeatable values; In addition, its optimal selectivity towards NO2 gas is crucial for accurate and reliable detection; Fuel cell technology forms the basis of the sensor, taking advantage of a patented capillary diffusion barrier to optimize its performance;

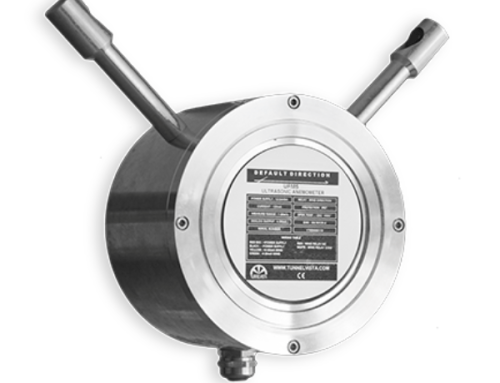

Physically, the detector is contained within a rugged aluminum alloy enclosure that meets IP66 protection standard; This housing houses a removable electrochemical cell, which has gold terminals to ensure a reliable electrical connection, along with the electronics required for signal processing; To maintain its efficiency over time, the detector is equipped with a breathing element made from a special sintered AISI 316 stainless steel filter; This filter, with a microporosity of 30 microns, offers exceptional protection against external contamination for both the electrochemical cell and the internal electronics of the device;

The combination of the stainless steel filter and capillary diffusion barrier contributes significantly to the detector’s durability; Despite this durability, it is recommended to replace the sensing element every two years as part of preventive maintenance; However, under specific working conditions, the electrochemical cell may have a variable service life, either shorter or longer than the standard two-year period;

This detector stands out for its exceptional reliability and outstanding performance; It is highly resistant to corrosion and is virtually immune to extreme variations in temperature or humidity; These features ensure that the detector provides accurate responses even in challenging environmental conditions and maintains a stable signal over time; Ultimately, the GE-NO2 gas detector ensures optimal response and unmatched stability, making it an ideal choice for industrial environments and other locations where safety is a top priority;

Features

- High stability and measurement accuracy

- Fast response and repeatability of values

- Automatic reset when the gas disappears

- Good chemical resistance and optimum chemical resistance and optimum selectivity

- Superior electrochemical cell Superior electrochemical cell

- Breathing element with sintered stainless steel filter;

- Easy replacement of the electrochemical cell Easy replacement of the electrochemical cell (max. 10 min)

- Power supply : 12 – 30Vdc (+/-15%)

- Power consumption : 1W max;

- Measuring range : 0 – 20 ppm NO2

- Analog outputs : 0 – 5V and 4-20mA

- Resolution : 0.1 ppm (at 20°C)

- Temperatura : -25 +55 °CResolution : 0.1 ppm (at 20°C)

- Humidity : 15 – 95% RH

- Pressure limit : 900 – 1100 mBar

- Repeatability : 1%;

- Linealidad : constante hasta +/-5% del fondo de escala (20ppm)- tiempo de respuesta: <20 seg.

- Stabilization time : 20 sec>

- Average sensor life : 2 years

- Housing : Aluminum alloy – Optional : AISI 304/316 stainless steel

- Protection rating: IP66

- Designed according to standards : EN50054 – EN50057

- Sensor certified according to BS5750Pt3 – ISO9002 – EN29002 standards;

- Control of road and railway tunnels

- Industrial pollution control

- Environmental control

- Control of combustion emissions Control of combustion emissions

- Process control